The airbag static initiator ATH-4S, as an upgraded version of the AT-4S, features optimized interfaces and enhanced performance. It simplifies testing for automotive airbags, gas generators, seat belts, and active hood systems. With the ATH-4S as the core component, engineers can quickly build the required initiation test system.

Auxiliary equipment:

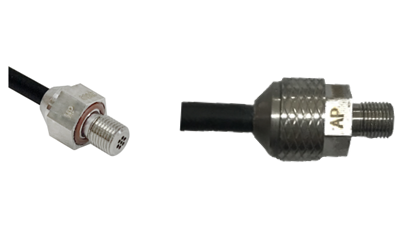

Pressure sensor

Product Features:

- 4-channel independent ignition output, supporting multi-stage ignition of airbags;

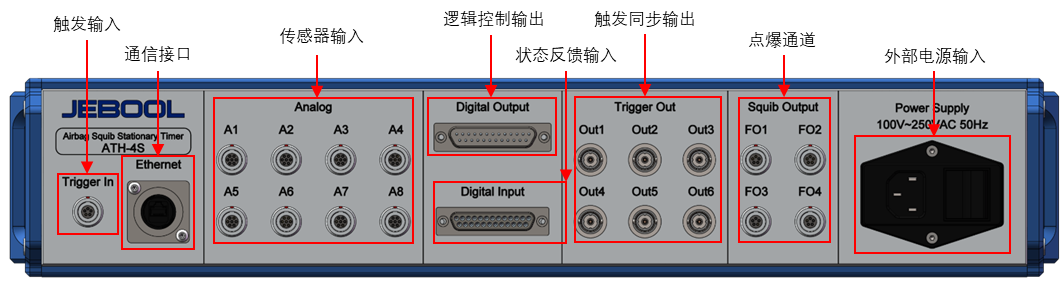

- Independent trigger input interface (Switch & TTL), compatible with buttons or for integration purposes (such as connecting to impact devices, speedometers, or switch sensors);

- Ethernet communication facilitates easy access to other networks;

- 8-channel sensor inputs with LEMO interfaces, compatible with sensors for gas pressure, force, displacement, acceleration, etc. 50kHz per channel synchronous acquisition, 16-bit A/D conversion, built-in data storage;

- 8-channel digital inputs for status feedback from peripheral devices (Safety Lock, camera armed, door lock, installation/movement in place of the ignition object, etc.);

- 8-channel digital output enables armed alarm output, supplementary light activation, high-speed camera ARM execution, door lock control, exhaust fan operation, etc;

- 6-channel synchronous trigger output, BNC interface, capable of triggering high-speed cameras and other data acquisition equipment;

- 100V~250VAC power supply;

- 19-inch 2U brushed aluminum chassis, can be placed on a desktop or rack-mounted in a control cabinet.

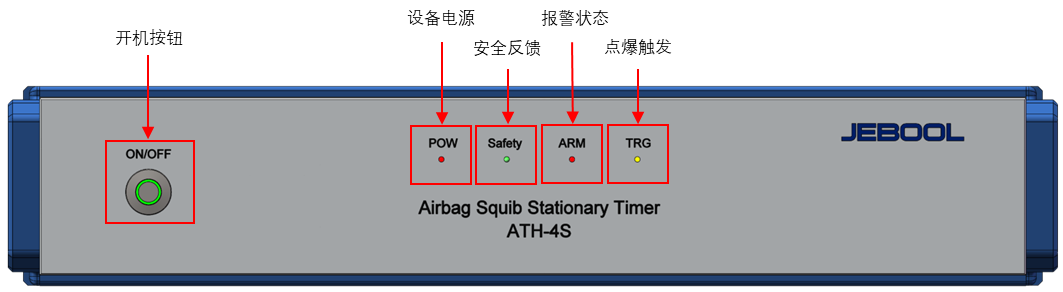

ATH-4S front panel

Rear panel of ATH-4S

ATH-4S side view

Point Burst Trait:

- Capacitor discharge type constant current ignition, dual closed-loop operational amplifier high-speed tracking technology;

- 4-channel ignition output, synchronous acquisition of ignition voltage and current;

- Automatic resistance detection, four-wire automatic compensation function;

- Ignition current adjustable from 1.00A to 3.00A (other ranges customizable);

- Current pulse width adjustable from 0.1ms to 5.0ms (other ranges customizable);

- Ignition delay adjustable from 0.2ms to 2000.0ms (other ranges customizable);

- Ignition voltage >18V.

- Provide the configuration data and resistance values for the firing circuit;

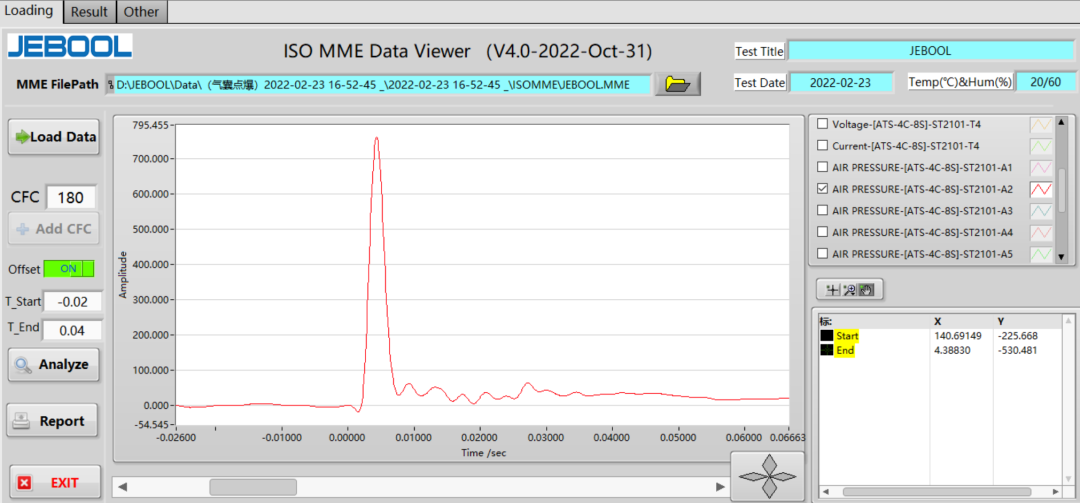

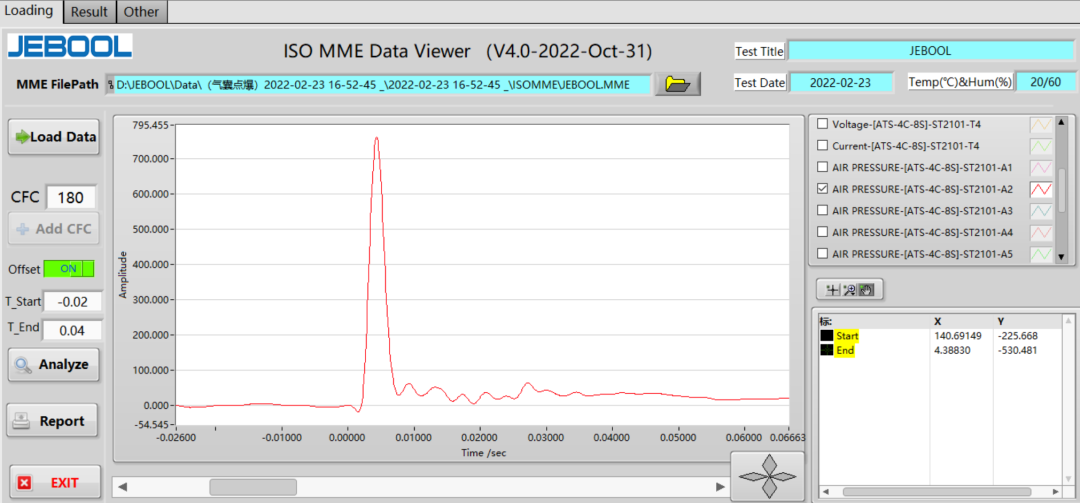

- Provide the original sensor and firing voltage/current data in CSV and ISO MME formats;

- Provide the ISO MME data viewing and processing tool MME-Viewer software, which supports data offset, CFC filtering, and filtered data extraction with Excel export.

Auxiliary equipment:

- Third-party high-speed cameras, fill lights, pressure vessels, etc., can be provided;

- Pressure Vessel:

- Used for generator explosion tests such as those for airbags;

- Complies with the technical requirements of SAE J2238 and USCAR-24;

- Available in two specifications: 60L and 28.3L;

- Manufactured using stainless steel welding technology, meeting the technical requirements of JB/T4709-2000;

- Complies with the product requirements of GB150-1998 for pressure vessels;

- Equipped with mounting holes for pressure sensors and other sensors, as well as a safety valve;

- Adjustable angle and movable.

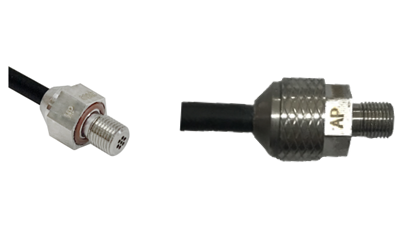

- Pressure Sensor: JEBOOL AP500K or MP500K for airbag explosion and pressure retention tests; AP1000K or AP2000K for pressure vessel tests.

Pressure sensor

- Displacement sensors (draw-wire type and laser reflection type);

- Trigger flash (for verifying the moment of explosion);

- Explosion control console cart (easy to move, can accommodate the exploder, computer, cable accessories, tools, etc.).

Explode the console cart

Explode the console cart